Railtrack Monitoring During Nearby Excavations – An interview with Victor Salinas

Worldsensing is a leader in IoT remote monitoring. It has over 3,000 network deployments around the world, in sectors including rail, mining and construction. Its solutions are primarily used to monitor how geotechnical, geospatial and structural conditions impact civil infrastructure to help prevent life-threatening incidents.

Railway News interviewed Victor Salinas, an Application Expert at Worldsensing about the benefits of using IoT monitoring to check for variations to track geometry when excavations are

underway nearby. He also discussed how this technology complements existing solutions so well.

What does IoT track monitoring bring to the table when it comes to excavation works taking place nearby?

Well, first of all you have to consider that some railways can be in remote, hard to access locations which can make inspection and monitoring much more difficult. By digitising

railtrack monitoring we offer remote, unattended and automatic inspection of a wide range of parameters.

IoT monitoring has a role to play throughout the lifecycle of a railway from the construction phase to commissioning and operation.

Excavations can affect the surrounding area in a variety of ways and so monitoring is key. This is especially the case when it takes place near existing, operational rail infrastructure,

as construction works can disturb settled soil in the vicinity, in turn potentially affecting the geometry of tracks and associated structures.

We can’t be there all the time, but with IoT we can define critical parameters – such as those related to track geometry – that can be continually monitored even when the workers

go home. This ensures we always know how an excavation is affecting the surrounding area and that existing infrastructure is within safe operational parameters.

Simply put, IoT monitoring provides a more detailed picture of the situation. When you need to monitor a large area the use of survey trains is probably the best approach to

collect high density spatial data regarding the geometry of the track. But when you detect a critical area, where data is required in a fast rate, this train approach becomes very expensive as it requires high operative costs. On top of this, they cannot be used when the line is operational, meaning monitoring isn’t possible during certain times of the day.

What other types of equipment have been used to monitor the effect of excavation works?

There are a range of ‘classic’ monitoring tools available. One, for example, can be applied to trolleys or strollers. These have a very low OPEX cost compared to the survey trains, but yet

require human intervention and interruption of the service during the survey.

For entirely remote monitoring, topographic systems such as prisms are a common solution, but as they use line of sight for measuring, they do have limitations. For example, rainy and

foggy days can affect monitoring, as can snow, which can cover the equipment entirely.

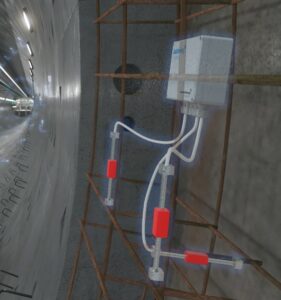

IoT devices can help to fill the data gaps from topographic systems. Tiltmeters, for example, monitor the tilt of a surface and can be installed directly onto sleepers. They offer a high

sampling rate, if required, depending on the scenario and activity. You might be happy gathering data once or twice a day, or you might want to take advantage of its ability to

provide updates every few minutes.

These features lead to a great synergy between the two approaches; topographic and IoT. The data coming from these two independent approaches offers a more robust dataset that

gives you a much better picture of the situation.

Simply put, topography and tiltmeters have lots of synergies and so complement each other

really well.

How do clients get the data these IoT devices gather?

Long range radio, which is a perfect solution for railway environments because it doesn’t interfere with rail operators’ transmission or telecommunication systems.

With clear line of sight, the information can be sent as far as 10-16 kilometres to a gateway device connected to the Connectivity Management Tool platform (CMT). This is a software

tool to manage the entire list of networks and devices and guarantee the data is properly pushed to the customer’s analytics software or visualisation tool with the required quality

and assiduously.

What other benefits come from removing manual monitoring in these scenarios?

Well, you’re removing the risk of human error but you also stop wasting time. With manual monitoring you’ve got all those man hours spent going into the field to capture the data, but

with human intervention you can also introduce errors and risk collecting bad data.

If it’s a cold day they might be rushing and not read a measurement correctly. If the visibility is poor there’s the risk of a similar problem. To add to this, you won’t know if that data’s

bad because there’s nothing to check it against.

In addition, if you need to raise the sampling rate there’s no quick solution if you’re using manual monitoring, as it takes time to send people back out into the field. With our IoT

devices, you can change the sampling rate at a click of a button.

Finally, and potentially most importantly, you’re improving staff safety. Sending workers out to remote and harsh environments can put them at risk of injury – this could be anything

from slipping down an embankment to getting hit by falling rocks.

IoT monitoring only adds benefits, making it a win-win option.

So where is your equipment currently being used to monitor rail infrastructure during

excavation works?

At the moment our systems are being used in several phases of construction for HS2. Thousands of tiltmeters have been deployed so far.

The UK is a region very well suited to our solutions especially since we are certified through Network Rail – as I mentioned, optical solutions have problems with many weather

conditions that affect the UK, such as fog and rain. So, these tiltmeters are of great help monitoring track geometry while construction is underway.

They’re also being deployed in a number of other countries including France and Germany, where the tech is being used to monitor SNCF and Deutsche Bahn (DB) infrastructure. This is

a necessity in France as it has a regulation stating any excavation near railway tracks must be monitored.

We’re working with a partner here, who also deployed prisms alongside an operational track to monitor what happens to the line when nearby excavation work takes place.

They’ve found that when they’re unable to monitor using the automatic automated motorised total stations (AMTS) they’re still able to see exactly what’s happening thanks to

our tiltmeters.

The benefits of using these solutions together are highlighted yet again with a project undertaken by Deutsche Bahn (DB). The company highlighted that the most robust

monitoring uses both AMTS and tiltmeters because these technologies complement each

other so well.

Source:

Article pag 177

Original source in german

EI – Der Eisenbahningenieur [Eisenbahn-Ingenieur]. Internationale Fachzeitschrift für

Schienenverkehr & Technik. 02|22.