Connect a wide range of geotechnical, structural, environmental and process monitoring sensors from the most relevant instrumentation brands worldwide.

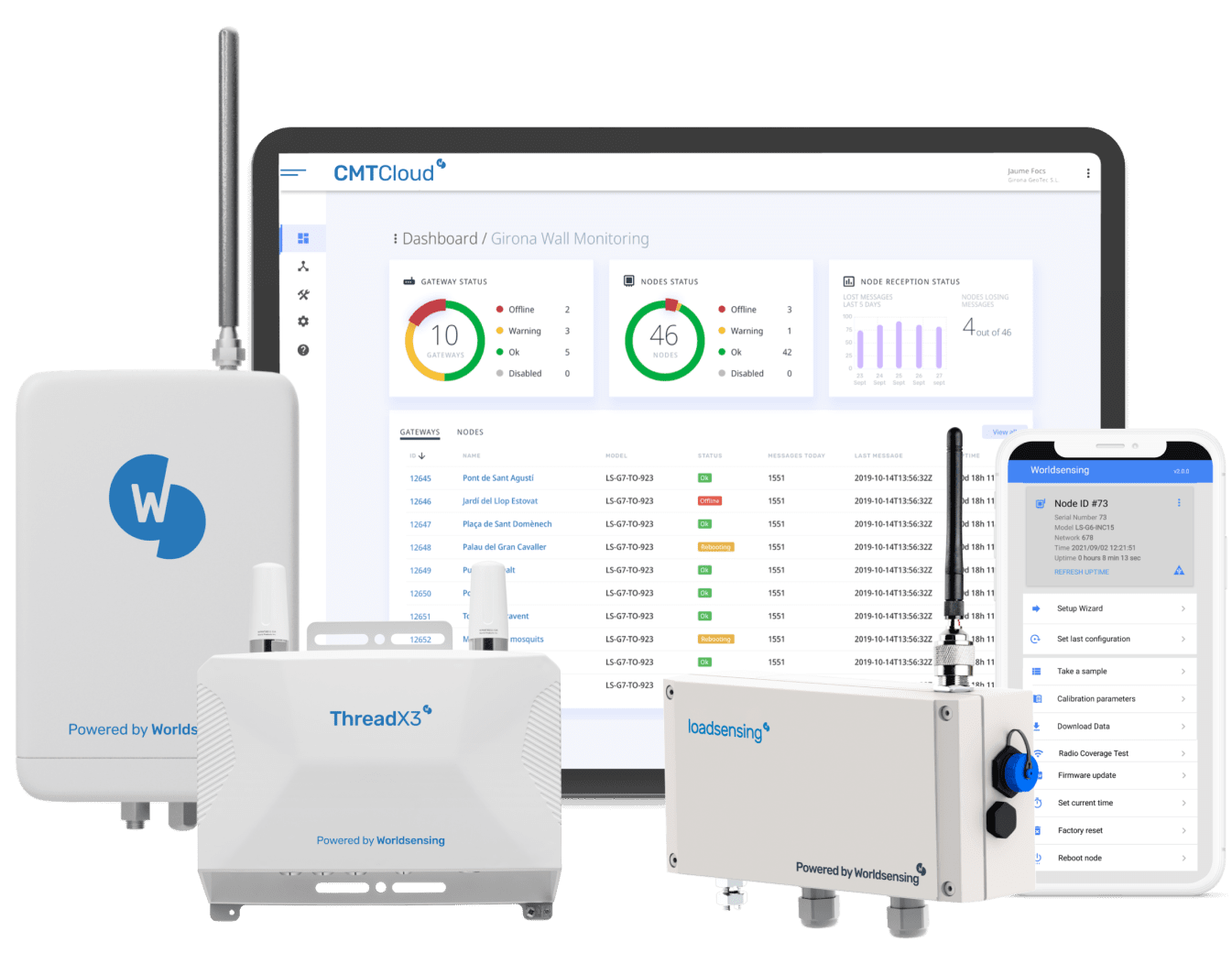

IoT Remote Monitoring Solution

3000 deployed networks across 70 countries, monitoring more than 170k sensors and instrumentation.

A system that lets you expand, change or reconfigure depending on the project needs.

Cover broadband and narrowband communications with a single network provider. The most complete catalog of sensor integrations in the industry.

Deploy robust, low-maintenance devices with up to 10 years of unattended operations.

Leverage the power of 5x more network coverage than other wireless solutions in the market. Cover narrowband and broadband communications with a single network provider.

Manage yor network deployment form a single software platform, from network to node configuration.

Discover how you can leverage IoT remote montoring in your undergorund projects

Take advantage of the widest compatibility with leading instrumentation and monitoring sensors and systems. We integrate with a wide variety of sensors through different communication protocols: vibrating wire, digital, and analog.

Sensor compatibility

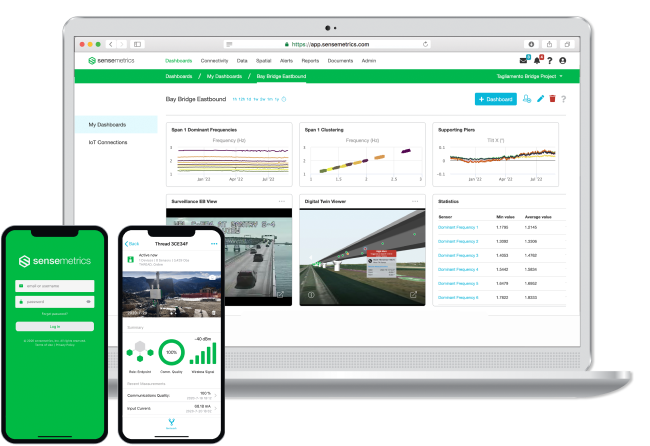

Enjoy the interoperability between CMT and your information systems through standard software communication protocols.

We have teamed up with Bentley, leading software provider for .. To offer an end-to-end solution that takes monitoring to the next level.

Worldsensing is the global leader in IoT remote monitoring. Our monitoring solution enables near real-time data acquisition of geotechnical, geospatial and structural sensors as well as remote device, data and network management.

Monitoring through 3,000 networks

Deployed in 70+ countries

Edge devices connected to over 170,000 sensors

Made in Europe

DESIGNED IN BARCELONA. MADE FOR THE WORLD.

Our solution is part of the most prestigious metro tunnel projects in the world such as the Purple Line Extension in the US, Grand Paris Metro Project in France and the Sydney and Melbourne Metros in Australia. Watch this video to see how we do it.

Acciona and Worldsensing present how they worked together to perform wireless monitoring in Túnel dels Tres Ponts in Lleida, Catalunya.

Watch Juan Perez give an overview of the wireless tilmeter range, especially its variant with an internal antenna which is ideal for rail applications.