Ensuring the safe delivery of a metro tunnel in Melbourne

Challenge

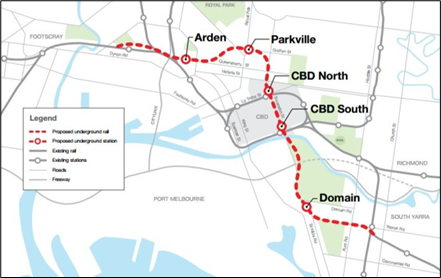

Melbourne’s Metro Tunnel Project will deliver twin nine-kilometer rail tunnels from the suburbs of Kensington to South Yarra, in addition to five new underground stations. Worldsensing Partner, Geomotion Australia, has been tasked with monitoring excavations and potential movements of surface and third party assets related to the construction of this project which is being designed and constructed by a public-private partnership joint venture.

The scope of works includes bored tunnels together with excavation of cut-and-cover stations, caverns and cross-passage of which must be monitored for below ground and surface movements. At any stage of the project, it is important to confirm that ground and support systems are behaving in accordance with the design predictions.

Solution

Geomotion has an important involvement in the monitoring of the excavation of the ground surfaces and selected third party assets related to project construction. Instrument installation started in 2018, just over five years later thousands of geotechnical instruments have been installed project-wide to ensure the full, in-depth monitoring of the construction area and its surroundings.

A wide range of geotechnical instruments have been deployed to provide data related to the potential movement risks to infrastructure. The instruments included tiltmeters, in-place inclinometers, strain gauges, beam electrolevels, extensometers, piezometers, vibrating wires, crack meters and load cells.

Instruments are connected to wireless data loggers, which are part of the Worldsensing IoT remote monitoring solution, to ensure effective transfer of data. Gateways collect the data from the LoRa-powered nodes spread throughout the project and send the data to the Connectivity Management Tool network monitoring software to help furnish a near real-time picture of the project’s critical aspects.

Benefits

Information from strain gauges, tiltmeters and other instruments allows construction management to monitor that the project is following the design.

Data from all instruments such as piezometers and load cells can also trigger pre-planned contingency actions to control risks associated with the construction work. Meanwhile, the Worldsensing equipment gathers instrument information in near real-time, which helps the construction team to make informed, timely decisions.

Are you planning a project?

Get in touch with us to share your needs and project requirements. We are experts in engineering and IoT and are happy to help.