Tailings dam monitoring for Boddington, Australia’s largest gold mine

Challenge

The Boddington Mine in Western Australia is Australia’s largest gold mine. It has a Residue Disposal Area (RDA) where it stores the mine tailings residue from gold and copper processing.

The mine owner, Newmont, previously deployed site personnel to manually monitor an extensive piezometer network around the RDA. This was a challenge because the facility covers an area of 12 square kilometers.

Solution

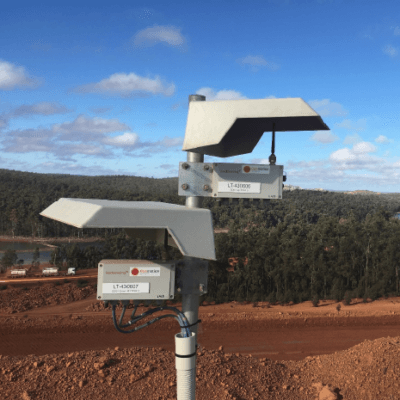

As part of Newmont’s RDA dam monitoring work, Worldsensing’s partner Geomotion Australia installed 34 Worldsensing vibrating wire 5-channel data loggers, servicing 125 piezometers in 45 locations, and a central gateway to send data to Newmont’s management software.

Worldsensing uses LoRa, a long-range, low-power wireless technology used by IoT networks worldwide, and a star network topology that can cover a range of up to nine miles or 15 kilometers without any repeaters. The wireless data loggers are also IP-67 certified and have been tested in temperatures ranging from -40C to +80C, so they are able to withstand the harshest environments.

Benefits

By upgrading from manual to wireless monitoring, the Boddington Mine benefits from the real-time monitoring of the tailings dam. This minimizes safety risks for site personnel and reduces the cost of monitoring such a large area.

Are you planning a project?

Get in touch with us to share your needs and project requirements. We are experts in engineering and IoT and are happy to help.