Monitoring water level, dewatering and pumping stations for an open-pit gold mine in Nevada, USA

Challenge

US gold mining has come a long way since the days when prospectors panned for nuggets in California. Today, deposits are excavated from massive open-pit mines and tons of gold-bearing rocks are heaped on waterproof pads then treated with sodium cyanide to leach out the gold.

The scale of these operations means safety is of paramount importance, since a pit wall collapse or leach pad leakage could have serious health, safety and environmental consequences. At one open-pit mine in Nevada, America’s top gold-producing state, operators were concerned about wall stability because of water seepage caused by runoff from a nearby mountain—and wanted to check for leaks on a pad. The challenge was how to monitor the water level, dewatering and pumping stations efficiently.

Solution

The initial phase of the project included the deployment of vibrating wire 1 and 5-channel data loggers connected to piezometers installed in and around the pit and elsewhere on the property for water level monitoring. The mining operator soon realized that, compared to rival wireless data acquisition systems, Worldsensing’s solution can transmit data over longer distances without the use of repeaters, can last longer due to ultra low-power consumption and features higher quality and ruggedized components and enclosures ensuring super low maintenance deployments in the harsh, Nevada environment.. This translates to a more cost-effective deployment with fewer equipment and reduced costs for installation and maintenance (e.g. for battery replacement).

Succeeding deployments included an additional rugged gateway providing connectivity to an ever-growing network of sensors across the operation. From the water level and dewatering stations in the open pit to water level monitoring at secondary sites across the property, and two more gateways and vibrating wire data logger networks on multiple leach pads, the Worldsensing network has expanded into hundreds of deployed devices with capacity for many more in the future. The project has also helped pave the way for the integration of In-Situ brand instruments resulting in the Worldsensing digital logger’s compatibility with the In-Situ Aqua and Level Troll sensors. This also demonstrates Worldsensing’s commitment to developing new and novel integrations with the instruments that clients depend on.

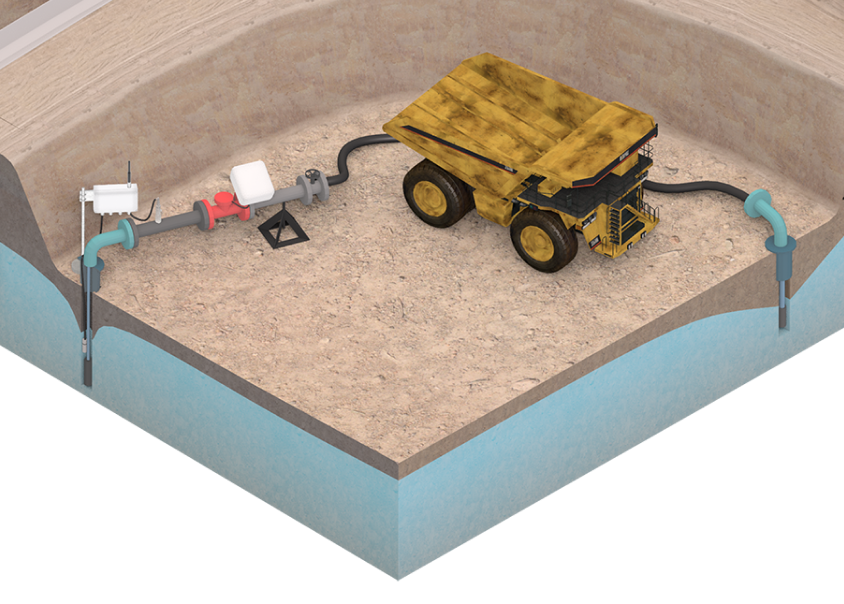

Recently, the operator also deployed Netafim IRT flowmeters connected to Worldsensing’s Piconode to automate the monitoring of dewatering pumping stations as well as pumping stations involved in the active injection of leachate into gold ore on the leach pads. This interesting combination is proof that even a small device such as the 1-channel, mini node Piconode is flexible enough to be immediately connected with the flow meters without any major integration.

The entire monitoring network and devices are monitored and managed through CMT Edge, an on-premise network management tool, capable of showing the status and health of all devices across the Worldsensing network and in turn is connected to the customer’s reporting and visualization software.

Benefits

The Worldensing Piconodes and Netafim sensors are battery-operated and use a dry-contact (extremely low voltage) connection so there is no need for an expert electrician to run mains power out to the devices and minimal maintenance is required because the devices can operate on the batteries for years. The low cost, flexibility and reliability of the Worldsensing Piconode along with its impressive transmission range, means it can be used to start remote monitoring not only in mining but also in a growing range of applications.

Across all these areas of the site, IoT remote, wireless communication avoids the threat of cables being cut by mining equipment. Worldsensing’s widely-compatible device range, especially the digital logger, make it easy to integrate the solution with other sensors and systems. Finally, the Worldsensing solution allows the mining operator to get regular, reliable data on water flows and levels, safeguarding and enhancing operations at a fraction of the cost that would be needed for manual monitoring.

Are you planning a project?

Get in touch with us to share your needs and project requirements. We are experts in engineering and IoT and are happy to help.