Wide-area monitoring of tailings dams in Brazil

Challenge

A Brazilian mine has a complex tailings dam monitoring system that covers 22 dams. The mine consultant in charge of dam monitoring, Worldsensing partner Tetra Tech, needed to gather real-time data from various sensors, including piezometers, water level sensors and inclinometers, installed across different tailings dams. The challenge was to find a cost-effective way to send the data to a database server and workstation, taking into account the fact that one site included seven dams with a 7 km radio range.

Figure 1: The red circles represent the radio ranges of different wireless solutions in optimal conditions. The outermost circle represents Worldsensing’s radio range in a site with 16 tailings dams.

Solution

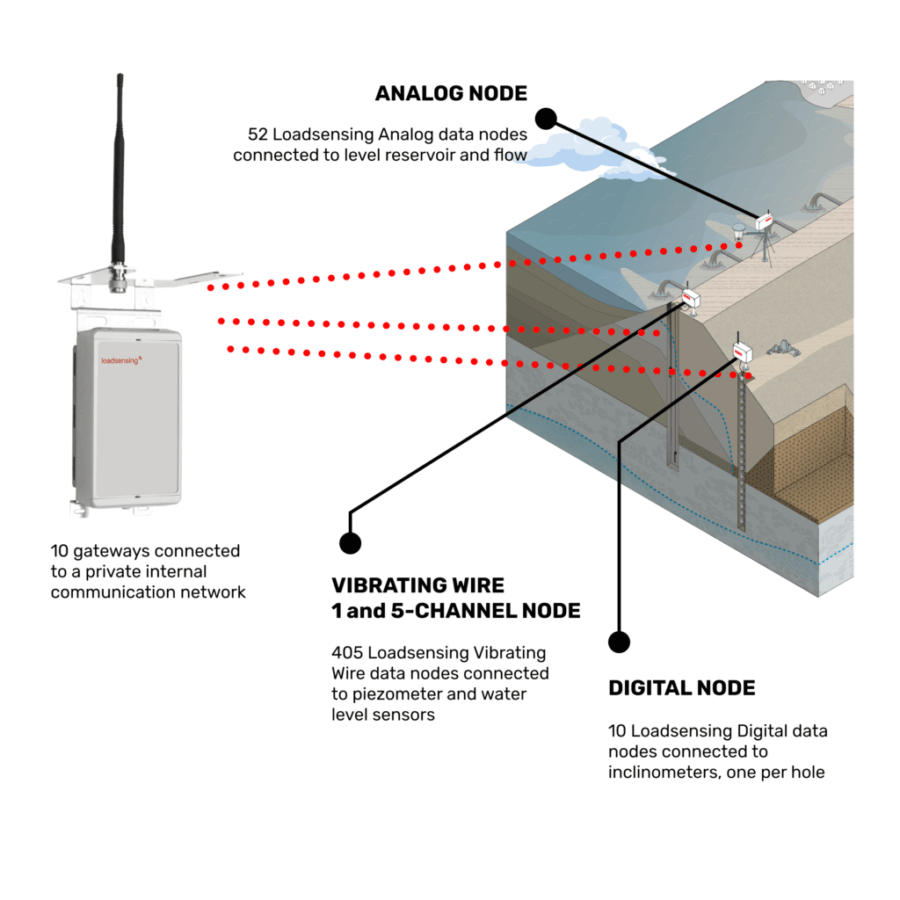

Tetra Tech opted to use a wireless monitoring system from Worldsensing and installed a network of 467 vibrating wire, analog and digital loggers to send real-time data to 10 gateways connected to the mine’s private network.

Two gateways at one of the sites receive data from 158 data loggers, including vibrating wire 1-channel data loggers connected to piezometers, analog data loggers connected to ultrasonic water level meters and digital loggers connected to chains of in-place inclinometers.

For connectivity, Worldsensing uses LoRa, a long-range, low-power wireless technology used by IoT networks worldwide. Features of the system include:

- A star network topology that can cover a range of up to nine miles/15 km without any repeaters.

- A radio sensitivity of up to -137 dBm, which makes the signal up to 32 times stronger than other wireless monitoring systems.

- Data logger casings that are IP-67 rated and have been tested in temperatures ranging from -40ºC to +80ºC.

- Certification by ANATEL, the telecommunications regulation agency in Brazil, making it apt for deployment across the country.

Figure 2: A Worldsensing vibrating wire 1-channel data logger connected to a vibrating wire piezometer.

Benefits

The wireless configuration of the data acquisition system eliminates the need for expensive cabling and manual monitoring. Laying cables in a tailings dam requires trenches and cable protection against issues such as embankment settlements. New sensors have to be added as the site grows, again requiring expensive cable installation. A wireless system provides data from sensors in near-real time, versus manually collected readings with a more sporadic periodicity and vulnerability to human error.

Worldsensing’s solution leads to savings of up to 30% on the acquisition of materials and infrastructure and up to 40% on installation. Reliable data on the behavior of the dam helps minimize risks and improve the safety not only of mine employees but also of local communities. Worldsensing contributes to the sustainable growth of the mining industry by ensuring compliance with safety regulations and standards.

About Tetra Tech

Tetra Tech is a leading provider of consulting and engineering services and a Worldsensing partner in Brazil. With 20,000 associates, Tetra Tech’s capabilities span the entire project life cycle in more than 450 offices around the world. Tetra Tech supports government and commercial clients by providing innovative solutions focused on environmental and social studies, compliance and environmental management, engineering, geotechnologies, geotechnical, environmental assessment and remediation, mine planning and oceanography, and water and coastal engineering. It is based in five cities: Belo Horizonte, Lima, Rio de Janeiro, Santiago and São Paulo, which provides services to the energy, oil and gas, ports, mining, socio-territorial planning, environmental, industries and infrastructure sectors.

Are you planning a project?

Get in touch with us to share your needs and project requirements. We are experts in engineering and IoT and are happy to help.