Improving the safety of metro tunnel construction monitoring

Challenge

Building tunnels is a painstaking affair. Massive tunnel boring machines (TBMs) grind through the earth, removing soil and laying segments of pre-cast concrete hoops in their wake to stop the roof from caving in. Even with the hoops in place, the tunnel is a potentially hazardous place. Engineers have no way of knowing if a concrete segment will fail until they have installed monitoring equipment that can check for stresses and strains.

Installing this equipment puts the safety of engineers at risk, particularly if there are vibrations ahead, so the TBM must pause for hours while the installation takes place. This slows down tunnel construction and adds to the cost. Working on the Grand Paris Express Metro Line 18 in France, experts from the structural consulting firm Sixense decided there had to be a smarter way to install tunnel monitoring equipment—and worked with Worldsensing on a groundbreaking new approach.

Solution

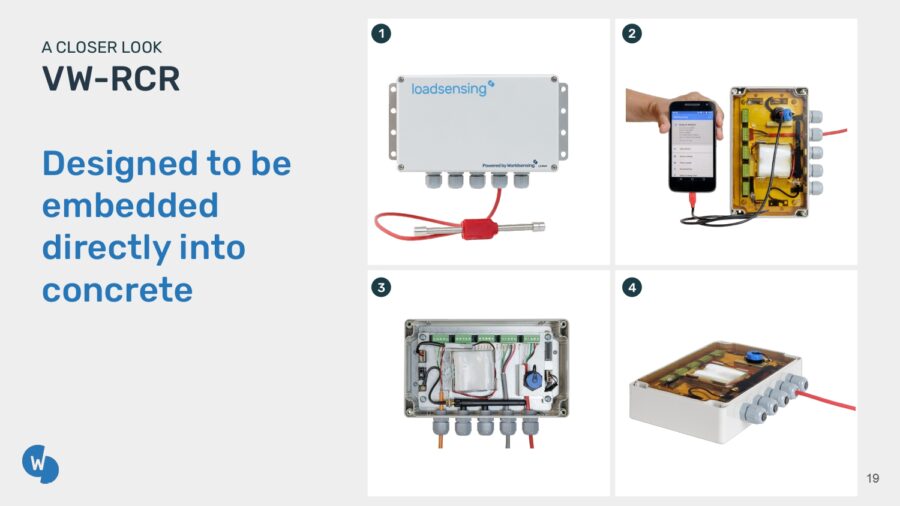

Instead of installing monitoring equipment in the tunnel after the lining was laid down, thought the experts, why not embed the devices within the lining itself? The concrete segments installed by the TBM are pre-cast off-site, so embedding sensors would be easy. To that end, Worldsensing came up with a special version of its vibrating wire five-channel data logger, encased in a rugged polymer casing that could be sunk directly into concrete.

All electronic components within the unit are protected with insulating resin, with only the device’s USB connections left open for configuration purposes. The data loggers are powered by batteries that can last up to a decade with no need for maintenance and the whole unit is placed in the concrete, within an external foam enclosure, to sit flush with the surface of the tunnel lining.

Benefits

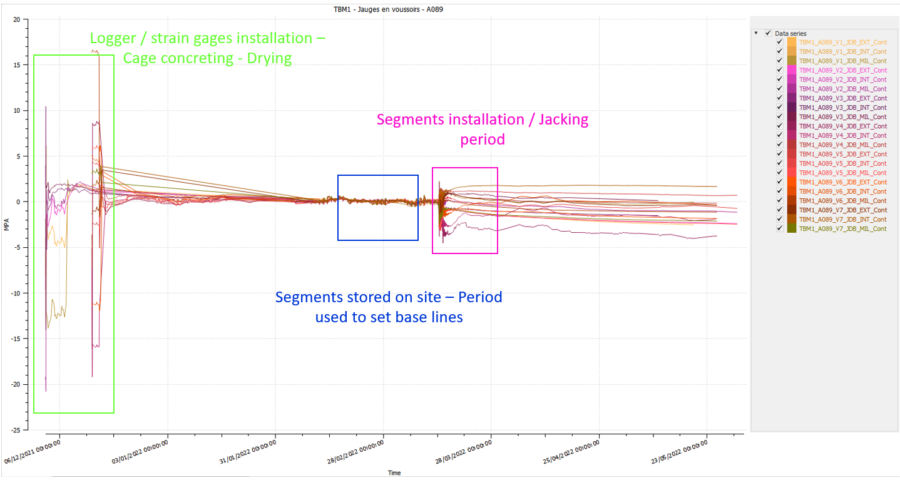

The data loggers are connected securely to vibrating wire sensors such as strain gauges or pressure cells and start delivering useful information from the minute they are installed, helping experts assess the structural strength of each concrete segment even during curing. During construction, the equipment is installed as part of the tunnel lining process and so there are no delays to operations and no risks to engineers.

Initially, each data logger can send signals to a gateway installed up to 100 m away in the head of the TBM, or elsewhere in the tunnel, providing an almost instantaneous, real-time view of structural stability from the moment the lining is fixed in place. And once the TBM is more than 100 m from a sensor, interference drops, and the data loggers can communicate with gateways placed up to 3 km from each other in a straight line or 800 m in a non-linear tunnel.

Are you planning a project?

Get in touch with us to share your needs and project requirements. We are experts in engineering and IoT and are happy to help.