DATA COLLECTION

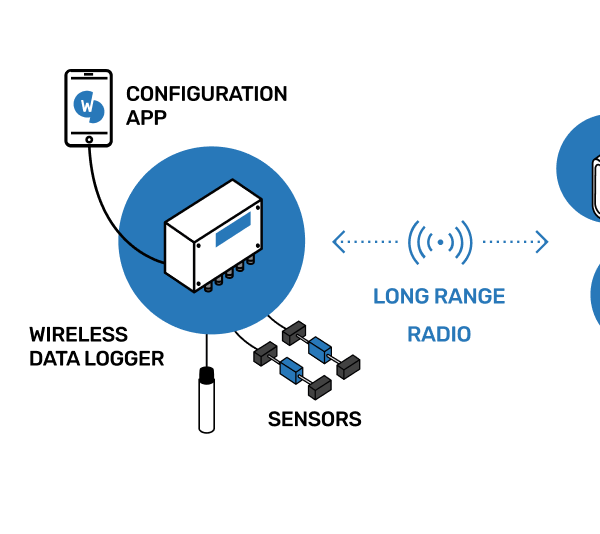

The analog 4-channel collects sensor data at your chosen sampling rate and sends it to the gateway.

The Analog 4-channel admits most inputs from analog sensors, such as voltage, 4-20mA, potentiometer, FWB, thermistor or PT100, allowing it to digitize load cells, strain gauges and pressure cells.

DOWNLOAD DATASHEETWorldsensing edge device

A wireless data logger

HOW IT WORKS

Simplify your projects through remote, automated monitoring.

Datasheet - Analog 4-channel

DEVICE COMPATIBILITY

Worldsensing wireless data loggers can store up to 200,000 readings from a single sensor. If a Worldsensing data logger loses its connection with the gateway, it stores the data locally which can be manually collected with an external device. In addition, the system detects the disconnection of the data logger and sends an alert email to fix the issue. Moreover, Worldsensing includes a cloud-based, multi-gateway network setup to ensure redundancy of data in case any gateway fails to send data. The system is designed to have multiple levels of control and implement a specific data management plan when unexpected situations occur: on one side, the data loggers use local memory when it is needed and, on the other side, a redundancy system of gateways is used to provide reliability when a specific concentrator does not work properly. Such architecture guarantees that the customers receive the gathered data in case of potential failures due to temporary malfunctions or loss of connections.

Worldsensing wireless edge devices are ruggedized and have been tested in temperatures ranging from -40ºC to +80ºC, so they can withstand harsh environments such as underground mines. Worldsensing is open to projects to test the depth limits of our monitoring solution and understand how ambient conditions may impact the network quality in deep underground mines. The Worldsensing laser distance meter data logger can be particularly useful for convergence monitoring. Worldsensing may be used as a last-mile solution inside deep galleries. The devices wirelessly send data to gateways underground that are connected to fiber-optic points used for machinery control and cameras, in order to transmit the data to the surface. Finally, Worldsensing wireless devices can read multi-point borehole extensometers, pressure cells and other frequently used sensors for underground monitoring.

Currently, the highest possible acquisition rate when using Worldsensing is one sample every 30 seconds, and the lowest is one sample every 24 hours. With such parameters the system can run for a long period, between 7 and 10 years.

Maintenance is minimal and depends on where the wireless device is located. After a short introduction and basic training, every employee is able to configure and maintain the devices and gateway through a mobile app. A monthly visual inspection is good practice, particularly in areas with activity. In addition, we recommended you inspect the wireless devices and sensor cables after detecting anomalous or missing readings. To minimize manual maintenance rounds, we offer a software to remotely manage deployed devices, data and networks. You can access the network status 24/7 and will receive an alarm in case of a downtime. Finally, another important maintenance requirement is batteries. Although batteries may last up to 10 years, it is good practice to schedule changes based on the battery life estimates and frequency of data acquisition.

Data protection and privacy are achieved through 128 AES [Advanced Encryption Standard] encryption on multiple levels, for all data being sent from the sensors to the application server and back.

Our newsletter will keep you up to date on everything related to Worldsensing, civil infrastructure resilience and IoT remote monitoring.

Please select one or all industries you are interested in.