Explaining Smart Ground Anchors

Smart ground anchors (also called ‘earth anchors’ in the US) are used in construction and civil engineering to stop embankments, side walls and similar structures from collapsing. Unlike standard ground or earth anchorage systems, smart ground anchors use data loggers to send information about the state of an anchor to a control center so the stability of the structure can be monitored.

This remote monitoring capability can help to significantly reduce the risk of accidents, since structural movements can be detected in near-real time and actions can be taken to stabilize the structure or evacuate the surrounding area, as required. This blog explains how smart ground anchors work and outlines their benefits compared to traditional anchorage approaches. For more information, read our e-book on Load Monitoring for Ground Anchorages.

Ground anchors: what are they and why do they matter?

Many construction and civil engineering structures, from retaining walls to tunnels, involve cutting into or piling up earth in such a way as to create walls or embankments that are unstable and pose a risk to people and objects below. To stabilize the earth, engineers cover it with an outer layer or skin, made of material such as concrete, which is held in place by large metal or glass fiber reinforced plastic pins or ‘tendons’ pushed into the substrate.

These tendons, which can be up to 70 meters long, are called ground, earth, percussion-driven-earth or mechanical anchors. Earth anchors are also used to affix guy wires for masts and other upright structures.

Monitoring ground anchors: why is it important?

The correct positioning, installation and monitoring of ground anchors is essential in assuring the stability and safety of the structures they hold in place. In practice, these structures can range from motorway embankments to radio transmission towers. The most important monitoring phase is immediately after ground anchors are put into place, as this is when they are most likely to move and be adjusted.

However, regular ground anchor monitoring is recommended (or mandated) throughout the lifespan of the structure, to make sure its integrity is not compromised by changing environmental circumstances. This process is not to be taken lightly; according to research, landslides alone kill around 4,000 people a year around the world, making it important to monitor the integrity of any banks of earth that could be liable to collapse near human activity.

Options for ground anchor monitoring

There are three main options for monitoring ground anchors, depending on the design of the anchor:

- A lift-off procedure with grip on anchor tails. This relies on pressure measurements carried out on filaments or ‘tails’ protruding from the anchor. Not all anchor designs have this, and those that do tend to be very bulky.

- A lift-off procedure with grip on a threaded anchor plate. This requires anchors with externally threaded anchor plates and oversized bearing plates. It also requires special stressing equipment with components such as a jack chair, and a connection element.

- A load cell procedure. This involves having a load cell permanently attached to the anchor, so loads can be monitored easily over time.

The third procedure is expected to grow in popularity since it is compatible with all ground anchor designs and does not require monitoring personnel to carry special equipment when carrying out readings on site. Furthermore, it allows readings to be carried out remotely via data loggers, potentially yielding near-real-time information with an extremely low cost per reading.

What are smart ground anchors?

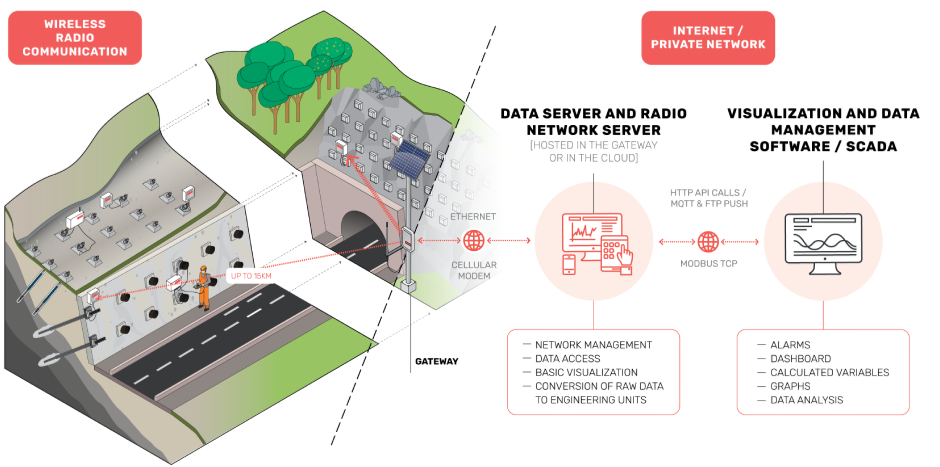

Having a load cell connected to a ground anchor means there is a device that is constantly monitoring the anchor’s condition. In a traditional setup, however, a technician would still have to visit a site to carry out load cell readings for the monitoring to yield useful information. But with the advent of wireless technologies it is now possible to attach a data logger to each load cell and transmit readings regularly to a gateway or base station. From there, the data can be analyzed and accessed from anywhere via an internet connection.

These so-called smart ground anchors can deliver condition data on an almost continuous basis if needed. The data loggers can be powered by batteries that may last for several years, doing away with the need for wiring or power installations. And they can be configured using a mobile app by people with no prior training.

Schematic diagram of a smart ground anchor setup

What are the advantages of smart ground anchors?

Compared to traditional ground anchor monitoring techniques, the use of smart technology offers the following advantages:

- Manpower. Because smart ground anchors can send data feeds automatically for years on end, they do away with the need for regular site visits by technicians. This allows experts can spend more time on value-added work. They only need visit a site in the event of a problem.

- Cost. An analysis by Worldsensing, shows the cost per reading for a smart ground anchor system is just €1.60 for an hourly feed over three years. This compares to around €3,480 per reading for manual readings carried out every quarter.

- Data. Smart ground anchor systems can transmit data every hour or even more regularly, giving engineers a near-real-time view of changes in structural integrity. This would allow technicians to spot sudden shifts that would not be apparent in quarterly or annual visits.

These three benefits combined add up to a very powerful argument for using smart ground anchor systems in any situation where there are significant risks and dimensions that might otherwise merit manual inspections. As pressure grows on construction and civil engineering project owners to avoid accidents that could result in loss of life, the safety benefits of better data analysis alone could justify a move to smart ground anchors.

- For further information on smart ground anchors, read our e-book on Load Monitoring for Ground Anchorages.